The extruder is the most important piece of equipment in a 3D printer.

FDM printers create models by layering filaments one layer at a time. The extruder is the tool that moves, heats, and extrudes the filament out of the printer. The type of extruder and print head used will affect the quality and style of the print. For this reason, it is considered an essential component of a 3D printer.

FDM printers create models by layering filaments one layer at a time. The extruder is the tool that moves, heats, and extrudes the filament out of the printer. The type of extruder and print head used will affect the quality and style of the print. For this reason, it is considered an essential component of a 3D printer.

In this article, we will discuss the basic information you need to know about extruders and print heads in 3D printers.

3D Printer Extruder Types 2024

Table of Contents

What is an extruder for a 3D printer?

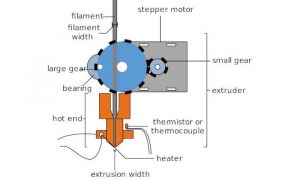

The extruder is the part of the 3D printer responsible for extruding the filament, melting it, and placing it on the bed to create the model. 3D printer extruders consist of multiple tools that serve different tasks. These are the cold end and the hot end.

The parts of the 3D printer that move, melt, and deposit the filament are called the cold end and hot end assembly. We may also simply refer to the part that moves the filament as the extruder and the part that melts it as the hot end.

The cold end is responsible for moving the filament to the hot end. A motor and gears work to move the filament through the PTFE TEFLON tubing (PolyTetraFluoroEthylene) or directly to the hot end. There are two types of cold ends with slightly different mechanisms, which will be discussed in the next chapter.

The hot end heats the material, melts it, and extrudes it layer by layer through a nozzle. The two main components of a hot end are

A “heater” that heats and melts the filament. The nozzle directs the filament as it is extruded.

Also Read: How to Clean Printer Heads Epson

Best 3D Printer Extruder | Comparison Table 2024

Top Quality | 5-Star Pick | Great Prices

| Image | Title | Buy | |

|---|---|---|---|

| Genuine Bondtech BMG Extruder (EXT-BMG) | Bondtech | VIEW ON AMAZON | |

| Micro Swiss Direct Drive Extruder for Creality CR-10 / Ender 3 Printers | Micro-Swiss | VIEW ON AMAZON | |

| BIQU H2 Extruder Direct Drive Extruder for Creality Ender 3 H2 V2.0 Dual Gear Extruder Not Stuck Direct Extruder 1.75mm Filament 270°C High Temperature Printing New Upgraded 3D Printer Kits | BIQU | VIEW ON AMAZON | |

| Official 3D Printer Extruder, Upgraded Aluminum Drive Feed Extruders Accessories for 3D Printer 1.75mm Filament Works with Creality CR-10 Series, Ender 5 Series, Ender 3 Series | Creality 3D | VIEW ON AMAZON | |

| WINSINN Dual Gear Extruder, Ender 3 v2 Upgrade Motor Shaft>20mm, Compatible with Ender 3 Pro CR10 Series 3D Printer TPU Filament Drive Feed | WINSINN | VIEW ON AMAZON |

Prices and images pulled from the Amazon Product Advertising API on:

Best 3D Printer Extruder | 2024 Product Overview

1. Bondtech BMG Extruder (EXT-BMG)

Product Overview:

Introduction: Looking to enhance your 3D printing experience? The Bondtech BMG extruder might just be the upgrade you need. Packed with innovative features and engineered for performance, this extruder promises to take your printing to the next level. But before you hit that “Buy Now” button, let’s delve deeper into what sets this extruder apart and what you need to consider.

Overview of 3D Printer Extruder Types: When it comes to 3D printer extruders, there are various types to choose from, each with its own set of advantages and disadvantages. From Bowden to direct drive setups, understanding the differences can help you make an informed decision.

Performance, Installation, and Compatibility: The Bondtech BMG extruder is designed for high performance and precision. With its Dual-Drive technology, you can expect reliable material feeding whether you’re using a Bowden or direct drive configuration. Plus, its compatibility with Nema17 stepper motors and built-in fitting for E3D hotends make installation a breeze.

Filament Handling: One of the key factors in achieving successful 3D prints is proper filament handling. The BMG extruder excels in this area, ensuring smooth and consistent filament flow, reducing the chances of clogs or jams.

User Experience: A seamless user experience is essential for enjoyable 3D printing. The Bondtech BMG extruder delivers on this front with its lightweight design, easy installation process, and hassle-free material feeding, allowing users to focus on creating rather than troubleshooting.

Reliability and Durability: Investing in a reliable and durable extruder is crucial for long-term satisfaction. The Bondtech BMG extruder is built to last, with high-quality materials and precision engineering that ensure consistent performance over time.

Price and Value: While the Bondtech BMG extruder may come with a slightly higher price tag compared to some alternatives, its performance, reliability, and durability make it a worthwhile investment for serious 3D printing enthusiasts.

Customer Support and Warranty: In the unlikely event that you encounter any issues with your Bondtech BMG extruder, you can rest assured knowing that you’re backed by responsive customer support and a solid warranty.

Additional Tips and Considerations: Before making your purchase, consider factors such as your specific printing needs, compatibility with your existing setup, and any additional accessories you may require, such as Bowden adapters.

- High performance and resolution.

- Low weight.

- Proven and reliable Dual-Drive technology.

- Works in both Bowden and direct drive applications.

- Compatible with a variety of filaments and materials.

- Bowden adapter not included.

- Only compatible with Nema17 stepper motors.

- The Thumbscrew tensioner may require frequent adjustment.

2. Micro Swiss Direct Drive Extruder

Product Overview:

Introduction

Enhancing your 3D printing experience hinges on optimizing every component, and the extruder is a pivotal part of that equation. Among the array of choices available, understanding the nuances of different extruder types and their compatibility with your printer can significantly elevate your printing game. Let’s dive into the realm of 3D printer extruders to uncover their intricacies and how they can impact your printing endeavors.

Overview of 3D Printer Extruder Types

3D printer extruders come in various types, each with its unique features and advantages. From direct drive to Bowden, and everything in between, understanding the differences in their mechanisms and performance can empower you to make informed decisions tailored to your printing needs.

Performance, Installation, and Compatibility

The performance of an extruder is paramount, dictating factors like filament control, printing speed, and accuracy. Installing the right extruder compatible with your printer ensures seamless integration and optimal performance, unlocking the full potential of your machine.

Filament Handling

Filament handling capability is a crucial aspect of any extruder. Whether it's accommodating different filament sizes or efficiently printing flexible materials, a high-quality extruder boasts exceptional filament handling capabilities, allowing you to explore a wide range of printing materials with ease.

- High-quality upgrade for Creality CR-10 and Ender 3 printers.

- Plug-and-play installation with no modification required.

- Dual-drive train and CNC precision-cut gears for improved performance.

- Adjustable filament grip for easy loading.

- A short, highly constrained filament path allows for flexible filament printing.

- May be more expensive than other extruder options.

- May not be compatible with other printer models.

- May require some setup and calibration to get optimal performance.

3. BIQU H2 Extruder

Product Overview:

- Lightweight (211 grams) and compact (76.8 x 38 x 77.2 mm) design.

- A unique cooling system that effectively dissipates heat.

- Capable of printing at temperatures up to 260°C (upgradable to 500°C).

- Compatible with a wide range of filaments (PLA, ABS, PETG, nylon, TPU/TPE).

- Compatible with many different 3D printers (including the BIQU BX and Creality Ender 3).

- May require the use of adapters to fit certain 3D printers.

- Not specified if the extruder is compatible with 3D printers other than the BIQU BX and Creality Ender 3.

- No information was provided on the durability or lifespan of the extruder.

4. Creality 3D Printer Extruder

Product Overview:

Introduction

Looking to enhance your 3D printing experience? Meet the red extruder, a durable and upgraded addition to your Creality 3D printer. With its high-quality aluminum alloy material and improved design, this extruder promises to elevate your printing game to new heights. In this guide, we'll delve into its features, performance, installation process, compatibility, filament handling, user experience, reliability, durability, price, customer support, and warranty, and offer some additional tips and considerations to ensure you make the most out of this valuable upgrade.

Overview of 3D Printer Extruder Types

The extruder is a crucial component of any 3D printer, responsible for feeding filament into the printer's hot end for melting and deposition. There are various types of extruders available, ranging from stock options to upgraded versions like the red extruder. Each type differs in design, materials, and performance, catering to different user needs and preferences.

Performance

The red extruder boasts an optimized design with metal extrusion and an original hot-end kit, ensuring smooth and consistent filament feed-in. Its beveled filament intake prevents scraping, minimizing the risk of print failures. With increased gear density and adjustable pressure, this extruder offers enhanced performance and reliability, pushing your printer to achieve finer details and higher-quality prints.

Installation and Compatibility

Installing the red extruder is a breeze – simply remove the old Creality extruder and screws, then effortlessly install the new one using the included accessories. Compatible with a wide range of Creality 3D printers including Ender-3 series, Ender-5 series, and CR-10 models, this extruder ensures versatility without compromising on performance.

Filament Handling

Filament handling is seamless with the red extruder, thanks to its advanced design that prevents jams and ensures consistent filament flow. Whether you're printing with PLA, ABS, PETG, or other materials, this extruder ensures reliable filament feeding for hassle-free printing.

User Experience

With its easy installation process, improved performance, and compatibility with various filament types, the red extruder enhances the overall user experience. Say goodbye to print interruptions and hello to smoother, more efficient 3D printing sessions.

Reliability and Durability

Crafted from high-quality aluminum alloy and subjected to surface oxidization, the red extruder is built to last. Its sturdy construction and optimized design make it a reliable companion for long-term use, ensuring consistent performance with minimal maintenance.

Price and Value

While the red extruder may come at a slightly higher price point compared to stock options, its superior performance, durability, and compatibility with a wide range of printers make it a worthwhile investment for enthusiasts and professionals alike. The value it adds to your printing setup far outweighs its initial cost.

Customer Support and Warranty

Rest assured, your investment is backed by excellent customer support and a comprehensive warranty. Should you encounter any issues or have questions regarding the red extruder, prompt assistance is just a message away. Plus, the warranty offers peace of mind, ensuring your satisfaction with this premium upgrade.

Additional Tips and Considerations

To maximize the performance of your red extruder, regularly clean it and ensure proper tension adjustments for optimal filament feeding. Experiment with different printing settings and materials to unleash its full potential, and don't hesitate to reach out to customer support for assistance or troubleshooting tips.

- Easy to install

- Made of durable, full-metal aluminum alloy

- Stable and reliable

- Improves the performance of 3D printers

- Adjustable bolt allows for customizable extruder pressure

- Only compatible with certain Creality 3D printers

- Not compatible with 3D printers using a direct drive setup

- Requires assembly by the user

5. WINSINN Dual Gear Extruder

Product Overview:

Introduction

Enhancing your 3D printing experience often begins with upgrading your printer's extruder. One popular choice among enthusiasts is the WINSINN Dual Gear Extruder, designed to elevate performance and durability. In this comprehensive guide, we'll explore everything you need to know about 3D printer extruders, focusing on how the WINSINN Dual Gear Extruder stands out in terms of installation, compatibility, filament handling, user experience, reliability, and value for money.

Overview of 3D Printer Extruder Types

3D printer extruders come in various types, each with its unique mechanism for pushing filament through the hotend. The WINSINN Dual Gear Extruder employs a double gear extrusion mechanism, offering high extrusion force for smooth feeding and precise retractions. Made of aluminum alloy, it ensures stability and durability, surpassing traditional plastic extruders in performance.

Performance, Installation, and Compatibility

Compatible with a range of 3D printers including Ender 3 series, CR10 S series, and Tornado, the WINSINN Dual Gear Extruder is a perfect replacement kit. However, note that it's designed for printers with motor shafts over 20mm, requiring a replacement stepper motor if the original shaft is too short. Installation is straightforward, though recalibrating E-steps (from 100 to 139) is necessary for optimal performance.

Filament Handling

The dual gear design of the WINSINN extruder ensures consistent filament feeding, reducing the risk of jams or uneven extrusion. This makes it suitable for a wide range of filament materials, from PLA to flexible TPU, offering versatility for various printing projects.

User Experience

With its stable and durable construction, the WINSINN Dual Gear Extruder enhances the overall user experience by providing reliable performance and smoother printing processes. Its precise extrusion and snappy retractions contribute to producing high-quality prints consistently.

Reliability and Durability

Crafted from aluminum alloy, the WINSINN extruder offers superior reliability and durability compared to plastic alternatives. Its robust design ensures long-term performance, reducing the need for frequent replacements and maintenance.

Price and Value

While the initial investment might be slightly higher than plastic extruders, the WINSINN Dual Gear Extruder offers excellent value for money considering its enhanced performance and longevity. With a one-year warranty and dedicated customer support, it provides peace of mind for your printing endeavors.

Customer Support and Warranty

WINSINN provides exemplary customer support, standing behind their products with a one-year warranty. Their commitment to quality assurance ensures that each product undergoes strict QC measures, guaranteeing satisfaction for customers.

Additional Tips and Considerations

Before purchasing, ensure compatibility with your 3D printer and measure the motor shaft length to avoid installation issues. Regular maintenance, such as cleaning gears and lubricating moving parts, can prolong the extruder's lifespan and optimize performance.

Investing in a quality extruder like the WINSINN Dual Gear Extruder can significantly enhance your 3D printing experience, offering reliability, performance, and value for money. With proper installation and maintenance, it becomes an essential component for achieving precision and consistency in your prints.

- High-quality, all-metal aluminum alloy construction.

- Improves stability and durability of the extrusion process.

- Compatible with various Creality 3D printers.

- Designed for use with a 1.75mm filament.

- The manufacturer provides a potential solution for gear wear issues.

- The Kit does not include a stepper motor or motor bracket.

- No instruction manual is included.

- Some customers have reported gear wear issues.

Types of Extruders for 3D Printers

There are two main types of extruders for commercial 3D printers: direct and Boden. Some types of 3D printers are also equipped with double extruders; let's take a look at the differences between the three.

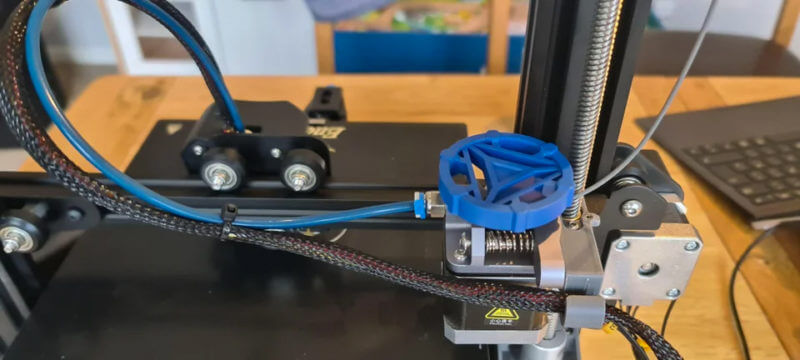

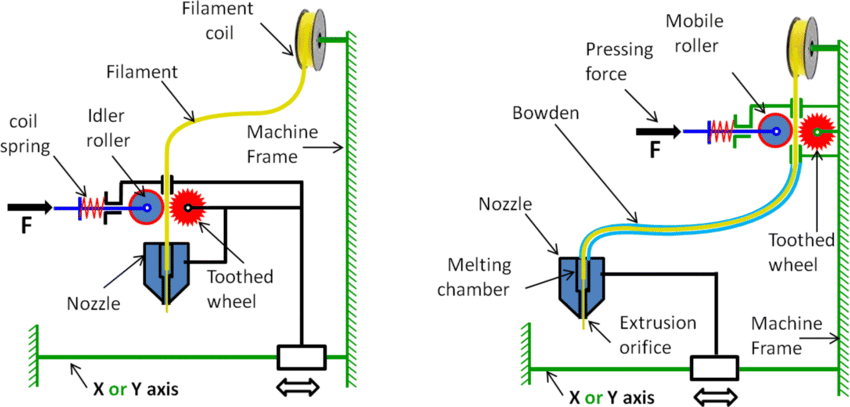

Direct extruder

In a direct extruder, the filament passes from the gear to the cold end and then to the hot end, all at once. In other words, the drive and gears that move the filament are mounted directly above the hot end.

Because the extruder is directly above the oven, it is heavier and slower. However, many people prefer to print flexible 3D filament using a direct extruder. Direct extruders allow the filament to travel a shorter distance before melting and settling. Therefore, problems are less likely to occur during the extrusion process.

Also Read: How to connect a Brother printer to WiFi

Bowden Extruder

Bowden Extruder

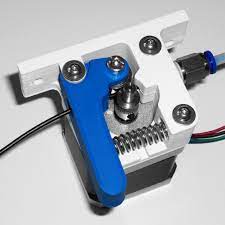

In a Bowden extruder, the cold end and hot end are separated by a PTFE tube through which the filament passes. Instead of placing the cold end directly on top of the hot end, the tubing separates the two parts.

Unlike direct extruders, Bowden extruders are extremely lightweight and fast because the only moving part is the hot end. The cold end, which has a drive unit, is positioned in a fixed position on the printer.

Bowden extruders can print high-quality patterns and are suitable for printing long, continuous patterns. It was once said that soft materials could not be used with Borden extruders, but that idea is now outdated. There are no gaps for filaments to move or twist, allowing them to move smoothly through the tube to the heating block.

Also Read: How to Clean a 3D Printer Bed

Dual extruders

In addition to various styles of extruders, some printers can be equipped with two or more extruders.

In addition to various styles of extruders, some printers can be equipped with two or more extruders.

Dual extruders allow you to print more than one material at a time or two models simultaneously. Dual extrusion speeds up the printing process because there are two tools to move, melt, and deposit the filament.

Dual extrusion can also be equipped with an independent dual extrusion system (IDEX). This means that each extruder operates independently. So while a typical dual extruder can run simultaneously, each IDEX extruder runs independently. This results in higher efficiency, increased productivity, and potential time savings.

Also Read: Cheapest Place To Buy Printer ink Online

Extruders

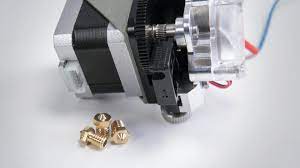

One cannot talk about extruders without mentioning hot ends. As mentioned above, the hot end is the part of the extruder that is responsible for melting the filament and pushing it onto the bed.

One cannot talk about extruders without mentioning hot ends. As mentioned above, the hot end is the part of the extruder that is responsible for melting the filament and pushing it onto the bed.

Depending on the nozzle installed, the hot end can be customized. Since the filament is extruded through nozzles, the size and type of nozzle you choose can have a significant impact on the style and effect of your model.

3D printers are equipped with a wide variety of nozzles, depending on the type of material and design to be printed. This subject is so vast that we could spend an entire article on it.

Also Read: How long does printer ink last before it dries up

If you are having trouble

If you are having problems with these printer components, it is most likely due to "insufficient extrusion," the most common printing problem with 3D printers. This problem is caused by inadequate extrusion of material into the printed part and manifests itself in the form of insufficient filament extrusion, missing layers, and spongy prints. Insufficient extrusion can be caused by

- Older software

- Wrong material selection

- Bowden tube condition

- Insufficient capacity

- Hot end problems

- Extruder board problem

- The extruder motor does not push the filament correctly.

3D Printer Extruder Types 2024 | Video Explanation

3D Printer Extruder Types 2024 | Infographic

Also Read: Which Printer has the Cheapest ink Cartridges

Conclusion:

The next time you look at a 3D printer, you'll appreciate a little more all the work that goes on inside the little device called an extruder, and like many other aspects of 3D printing, understanding this tool and how it works will help you become a more efficient user and improve the quality and features of your prints.

This product was presentation was made with AAWP plugin.