When I got the Circuit Maker, I immediately started playing with the adhesive vinyl, making beautiful labels for recycling jars, stickers for laptops, and heat-transfer vinyl for tote bags. I love it, but it is an expensive machine and I wanted to use it for other purposes.

While doing some research, I found an ink product that allows you to use a Circuit cutter and heat transfer the ink onto blank paper for t-shirts, coasters, etc. The concept of penetrating ink was a great idea and led us to consider dye sublimation printing.

Also Read: How to keep printer ink from drying out

What Is Sublimation Printing 2024

Table of Contents

What Is Sublimation Printing

Sublimation is a concept that everyone would have learned in high school chemistry. It is the process of going directly from a solid to a gas without going through the liquid stage.

When ink (which is solid on paper) is heated, it becomes a gas, which is then injected into the transfer material and cooled to become solid again on the substrate.

This concept keeps the colours vibrant and the fabric soft. The difference between dyed and undyed fabrics is barely perceptible.

If this process is not done correctly, it can result in white folds or ghostly designs. This wastes time and money. You should always test several designs before mass production to familiarize yourself with the machine and how the design will apply to the fabric.

Try a simple pattern first, rather than one that covers the entire fabric. Once you are comfortable with it, try more detailed designs.

Also Read: How to Clean Printer Heads Epson

Process of the Sublimation Printing

Process of the Sublimation Printing

How does sublimation printing work? After deciding on a design, it is printed on special paper using a dye-sublimation printer. The design is then printed on the fabric by either a heat press or (if done at home) pressure baking.

Transfer paper (usually sublimation paper) must be used to transfer the design to the fabric. The ink and fabric adhere to each other so that the ink is embedded and remains vivid longer (compared to other printing processes). The heat from the press or oven opens the pores of the cloth, and the pressure on the cloth cools the ink to a solid state. The press is then released and the paper is gently removed from the shirt or cup (or whatever you have been using).

With a compact dye-sublimation printer and a heat press, this process can be inexpensively reproduced at home. It is an effective and creative way to create designs that are out of the ordinary.

Also Read: How to connect a Brother printer to WiFi

Sublimation Materials

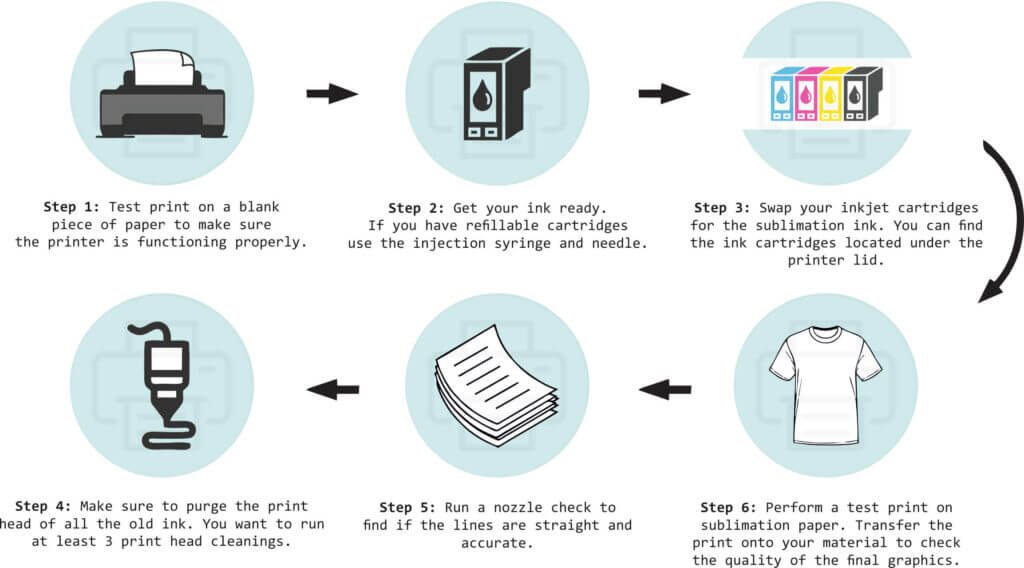

To print a design on a product with dye-sublimation printing, you need a few things. First, of course, you need a printer that supports dye-sublimation printing and can use dye-sublimation ink cartridges.

To print a design on a product with dye-sublimation printing, you need a few things. First, of course, you need a printer that supports dye-sublimation printing and can use dye-sublimation ink cartridges.

Second, you will need to invest in a heat press to print your design on fabric. If you want to print your design on ceramic mugs, you will need to purchase a mug fastener and a press. It is important to think carefully about the material you choose to use for sublimation printing because not just any material will do. You will also need transfer paper (for sublimation or copying), and you will need to invest in RIP software for colour correction.

Also Read: Which Printer has the Cheapest ink Cartridges

Fabric for sublimation printing

If you are starting a printing business and want to use sublimation printing or start using it at home, it is important to know what materials are available. These materials include

If you are starting a printing business and want to use sublimation printing or start using it at home, it is important to know what materials are available. These materials include

- Polycotton fabrics

- Polymeric materials

- Polyester

- Ceramic

- PVC

- Polyester coated aluminium

- Polyester coated metal

- Polyester Fabric

- Polyester coated plastic

Based on the above, it can be said that the best materials for sublimation printing are polyester and ceramic. While traditional printing allows only one logo per garment, fabrics allow a variety of designs and logos.

However, there are some designs that are not suitable for sublimation printing. For example, a brightly coloured design may be placed throughout a garment. This is because of the risk of ghosting, colour shift, and white splash, which are also disadvantages of sublimation printing, discussed below.

Are there any materials that are incompatible with sublimation? Natural materials such as 100% cotton are not suitable for this printing method. This is because they do not have the necessary pores to absorb ink. Digital printing may be more suitable for such materials.

Also Read: How to Clean a 3D Printer Bed

Dye-sublimation heat press

There are many types of heat presses available, ranging from economical to those suitable for commercial use. The size of the heat press you purchase will, of course, depend on how you intend to use it.

There are many types of heat presses available, ranging from economical to those suitable for commercial use. The size of the heat press you purchase will, of course, depend on how you intend to use it.

If you are looking for a press that can handle a variety of functions, the Super Deal Pro 5 may be the best choice, while the Promo Heat Swing-Away sublimation transfer machine may be suitable if you are only looking for T-shirts.

As with any dye-sublimation printer, it is important to read online reviews before purchasing. If you will be doing this work at home, you will not need the capabilities of an expensive press. Therefore, investing in a lightweight, the multi-functional device may be the best choice.

As already mentioned, sublimation heat presses are the most expensive equipment. Without it, however, you will not be able to successfully print designs on your products. You need the pressure and heat that the heat press produces.

Also Read: How long does printer ink last before it dries up

Other Accessories

Once you have a printer (using dye-sublimation ink) and a thermal press, you’ll need a few other things.

- Paper – you can use special dye-sublimation paper, but I’ve seen people get very good results using copy paper. The paper isn’t very expensive, so it’s worth trying both options to see the difference.

- Butcher Paper – Butcher paper is used to putting a project between the heat press plates. This protects the heat press without leaving paint marks.

- Heat tape – This comes in handy for securing the design to the butcher paper so it doesn’t slip off.

- Tweezers – paper and designs can get very hot. Gently lift the sublimation printing paper with the tweezers to see if you need to apply more heat.

- What to print – T-shirts (polyester or high polymer blend), decorative items, sublimation printing coated tiles, etc.

- Wrap paper cutter – optional, good for cutting large rolls of butcher paper.

Also Read: Cheapest Place To Buy Printer ink Online

What Is Sublimation Printing 2024 | Video Explanation

What Is Sublimation Printing 2024 | Infographic

How can I use Circuit for sublimation printing?

The only drawback to Circuit’s Cut & Print option is that there is a limit to the size of the image that can be printed – 9.25″ x 6.75″. The reason for this size limitation is the black line that is printed around the image so that Circuit knows where the image is on the paper.

I used Circuit for dye sublimation printing because it cuts right around the image (no borders) and places multiple images on the project during the warm-up phase. This prevents ink and lines from getting on the paper of my projects.

I mostly make small items like bags, plates, jewellery, etc.,

so I don’t have to worry about size limitations, but I have made a few t-shirts, so this cutting feature is very useful.